How Figure AI Built a Robot in 12 Months

It usually takes a decade to build a humanoid robot.

Boston Dynamics spent 30 years perfecting Atlas. Tesla has been grinding on Optimus for years.

Brett Adcock built Figure AI in 12 months.

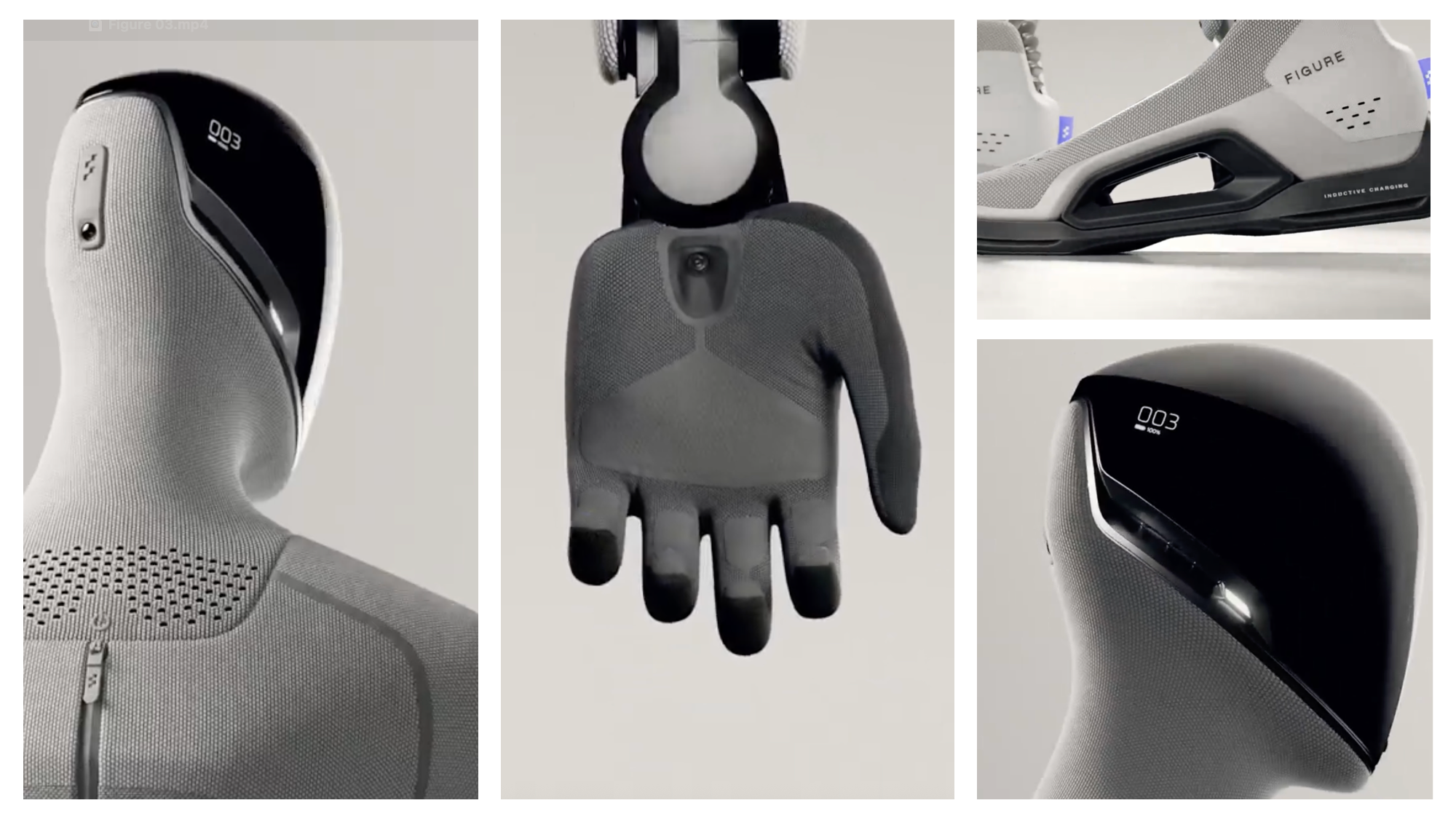

In under two years, he went from “Zero” to a $2.6 Billion valuation, a robot that can walk, make coffee, converse with humans in real-time (thanks to OpenAI), and work on a BMW assembly line.

He didn’t just build a robot; he built the fastest-growing hard tech company in history.

Here is how the “Archer Aviation” founder is trying to solve the global labor shortage before the decade is out.

The Problem: The Math of Extinction

Brett’s thesis is simple: We are running out of humans.

Birth rates are collapsing globally. The ratio of retirees to workers is skyrocketing. There are 10 million unfilled jobs in the US alone, mostly in dangerous, dull, or dirty warehousing/manufacturing roles.

We can’t print more people. But we can print humanoids.

The Playbook: “The Master Plan”

Brett Adcock is a student of the Elon Musk school of “Master Plans.” He published his vision on Day 1:

- Build a commercially viable humanoid. (Not a research project. A worker.)

- Deploy into the workforce. (Warehouses first, then homes.)

- Drive the cost down. (Ideally to the price of a cheap car.)

Most robotics companies get stuck in “Lab Purgatory”, trying to make the robot do backflips. Adcock ignored the acrobatics. He focused on Utility.

Can it pick up a box? Can it place it? Can it do it 1,000 times without falling?

The “ChatGPT Moment” for Robotics

The hardware is impressive, but the Software is the revolution.

In early 2024, Figure dropped a video that broke the internet. A human asks Figure 01, “Can I have something to eat?”

The robot pauses, identifies an apple on the table, hands it to the human, and explains why it did so, all in a natural, stutter-free voice.

This was the result of a partnership with OpenAI. They put the brain of GPT-4 into the body of a robot. Suddenly, the robot wasn’t just following code; it was reasoning.

The BMW Validation

While competitors were posting CGI renders, Adcock signed a commercial deal with BMW Manufacturing.

Figure robots are being deployed to the Spartanburg, SC, plant—the largest BMW exporter in the world. They aren’t there to replace skilled mechanics; they are there to move crates, organize parts, and do the “runner” jobs that humans hate.

Founder Lessons: Speed is a Choice

- Hire Mercenaries. Adcock didn’t hire juniors. He aggressively poached the best engineers from Boston Dynamics, Tesla, Apple, and Google DeepMind. He paid top dollar to assemble the “Avengers of Robotics.”

- Build in Public. Most hard tech founders are secretive. Adcock posts raw videos of the robot failing, walking, and learning. This created a massive viral loop that attracted investors (Microsoft, Nvidia, Jeff Bezos) and talent.

- Skip the Research. Figure isn’t a university lab. Every line of code is written with “Commercial Deployment” in mind. If it doesn’t help the robot get a job, they don’t build it.

Final Word

Brett Adcock is proving that “Hard Tech” doesn’t have to be slow.

By combining the manufacturing discipline of aviation with the reasoning power of AI, Figure is racing to become the first company to put a humanoid in every home.

The age of the Jetsons isn’t 50 years away. It’s walking off the assembly line right now.